Introduction

Applied statistics and probability form the backbone of engineering practices. These concepts help engineers make informed decisions, optimize processes, and solve complex problems. Imagine you’re an engineer tasked with designing a bridge. You need to consider various factors, such as load capacity and material strength. Here, statistics and probability come into play, guiding you through uncertainties and enabling you to predict outcomes based on data.

Engineers rely on these tools to interpret data, identify trends, and make predictions. For instance, they analyze historical data to forecast future performance or assess risks in projects. This is crucial because engineering decisions can have significant safety implications. Whether it’s designing a new product or ensuring quality control, statistics help engineers quantify uncertainty and improve reliability.

In this guide, we will cover several key areas. First, we’ll explore the role of statistics in engineering, highlighting its importance and real-world applications. Next, we’ll dive into the fundamentals of probability, which is essential for understanding risk and uncertainty in engineering scenarios. By the end, readers will have a solid grasp of how applied statistics and probability can enhance engineering practices, ultimately leading to better outcomes in their projects.

The Role of Statistics in Engineering

Understanding Engineering Statistics

Statistics, in the context of engineering, is the science of collecting, analyzing, and interpreting data. It provides engineers with the tools needed to make sense of complex information. By applying statistical methods, engineers can summarize data, identify patterns, and draw conclusions that inform their designs and decisions.

In engineering, statistics aids in various processes. For example, it helps in quality control, where engineers analyze production data to maintain standards. It also plays a crucial role in experimental design, allowing engineers to conduct tests and evaluate the effectiveness of different approaches.

If you’re looking for a comprehensive resource to dive deep into the world of statistics, consider getting Applied Statistics and Probability for Engineers by Douglas C. Montgomery. This book is a must-have for anyone serious about mastering statistics in engineering!

Real-World Applications

Statistical applications in engineering are vast and varied. In civil engineering, for example, engineers use statistics to assess the reliability of materials. They might analyze data on past performance to determine how much load a material can safely bear.

In mechanical engineering, statistics is essential for quality control. By monitoring production processes and analyzing defect rates, engineers can identify areas for improvement. A classic case study is the automotive industry, where manufacturers use statistical process control to ensure vehicles meet safety standards.

Speaking of statistics, if you’re interested in exploring the foundational concepts further, check out Engineering Statistics by Douglas C. Montgomery. It’s an excellent resource for engineers looking to understand statistical concepts in depth.

Electrical engineers also rely on statistics to optimize circuit designs. By analyzing failure rates and performance data, they can improve reliability and efficiency. These examples illustrate that regardless of the engineering field, statistics is a vital tool for problem-solving and decision-making.

Fundamentals of Probability

Basic Probability Concepts

Probability is a measure of the likelihood that an event will occur. In engineering, it helps quantify uncertainty. Engineers use probability to evaluate risks and make informed decisions. Understanding key terms like sample space and events is essential. The sample space is the set of all possible outcomes of an experiment, while an event is a specific outcome or group of outcomes.

For instance, consider a scenario where an engineer is testing a new material. The probability of the material failing under stress can be estimated based on past data. This estimation helps engineers assess whether the material is suitable for their application.

Probability also aids in decision-making when multiple outcomes are possible. Engineers can use probability distributions to model various scenarios, such as the lifespan of a product or the risk of system failure. By applying these concepts, engineers can make more reliable predictions and ultimately enhance their designs and processes.

To further understand probability, consider reading Introduction to Probability and Statistics by William Mendenhall. It’s a fantastic resource to build a solid foundation in probability concepts!

Probability Rules and Theorems

Probability rules are essential for engineers navigating uncertainties. The two fundamental rules are the addition and multiplication rules.

The addition rule helps when dealing with mutually exclusive events. For example, if you want to find the probability of either event A or event B happening, you simply add their probabilities. So, if A is rolling a 3 and B is rolling a 5 on a die, the probability of rolling either is P(A ∪ B) = P(A) + P(B). Easy peasy, right?

Now, what if you want both events to occur? Enter the multiplication rule! This rule applies to independent events. Imagine trying to calculate the chance of rolling a 3 on one die and a 5 on another. You’d multiply their probabilities: P(A ∩ B) = P(A) × P(B). It’s like making a delicious sandwich; you need bread and filling!

Next up is Bayes’ theorem. This theorem is a powerful tool for updating the probability of a hypothesis based on new evidence. In engineering, imagine you’re assessing a new material’s performance. You start with an initial belief about its strength, but as you gather data, Bayes’ theorem helps you refine that belief. For example, if tests show the material fails under certain conditions, you can adjust your probability estimates accordingly. This is crucial for risk management in engineering!

Random Variables

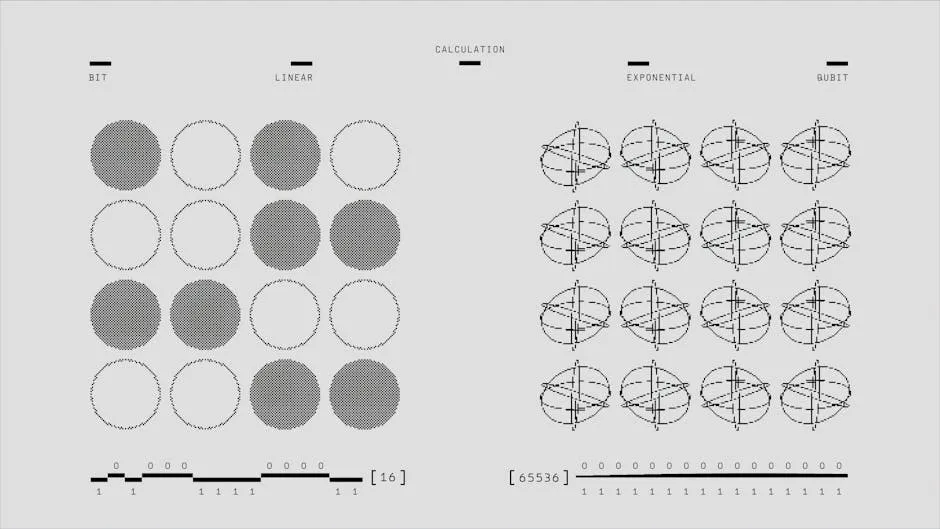

A random variable is a variable whose value is determined by the outcome of a random process. There are two main types: discrete and continuous.

Discrete random variables can take on a countable number of values. Think of the number of defective items in a batch. You can list out values like 0, 1, 2, and so on. Meanwhile, continuous random variables can take any value within a range, such as the time it takes to complete a task. This could be any value between, say, 0 and 60 minutes.

Understanding random variables is vital for modeling engineering processes. They allow engineers to quantify uncertainty and variability in processes. For instance, if you’re designing a bridge, a random variable might represent the load it will bear. By analyzing these variables, engineers can predict how structures will perform under different conditions, leading to safer and more reliable designs.

Discrete and Continuous Probability Distributions

Discrete Probability Distributions

Discrete probability distributions represent the probabilities of the outcomes of discrete random variables. Two commonly used distributions in engineering are the Binomial and Poisson distributions.

The Binomial distribution is ideal when there are two possible outcomes, like success or failure. For instance, if an engineer conducts a series of tests on a new product, the probability of it passing a certain number of tests can be modeled using this distribution. It helps in quality control processes where you want to assess the likelihood of a certain number of defects in a sample.

On the other hand, the Poisson distribution is useful for modeling the number of times an event occurs in a fixed interval of time or space. Engineers might use it to predict failure rates of components over time. For example, if a mechanical part has a known failure rate, the Poisson distribution can help estimate how many failures may occur in a year.

Curious about how these distributions impact engineering decisions? Check out Statistics for Engineers and Scientists by William Navidi. This book provides practical insights into how statistics can be applied in engineering contexts!

Continuous Probability Distributions

When it comes to continuous random variables, two key distributions are the Normal distribution and the Exponential distribution.

The Normal distribution is the classic bell curve. It’s essential in engineering because many phenomena naturally follow this pattern. For instance, the strength of materials often follows a normal distribution, allowing engineers to make predictions about material performance based on average values.

The Exponential distribution, on the other hand, models the time until an event occurs, like the time until a machine fails. This distribution is crucial in reliability engineering. By understanding the failure rates of components, engineers can design more reliable systems and conduct maintenance more effectively.

In quality control, both distributions play significant roles. Engineers can use them to analyze product lifetimes and determine acceptable failure rates, ensuring products meet stringent quality standards. Understanding these distributions is critical for making data-driven decisions in engineering practices.

Statistical Inference

Point Estimation and Confidence Intervals

Point estimation is like taking a snapshot of a population parameter. It gives you a single value that estimates something about the entire population. Common methods for point estimation include the sample mean and sample proportion. These estimates are essential tools for engineers, helping them make sense of data without needing to survey every single member of a population.

However, a single point estimate can lead to uncertainty. That’s where confidence intervals come into play. A confidence interval provides a range of values within which we believe the population parameter lies. Engineers often use a 95% confidence interval, which means we are 95% sure that the true parameter falls within this range. This range helps in risk assessment and decision-making processes.

Imagine an engineer assessing the strength of a new alloy. Instead of just reporting the average strength from a limited sample, they present a confidence interval. This interval informs stakeholders about the uncertainty associated with the strength measurement. It’s a vital aspect of engineering analysis, ensuring that decisions are backed by solid statistical reasoning.

Hypothesis Testing

Hypothesis testing is like a courtroom drama—there’s a defendant (the null hypothesis) and an alternative hypothesis fighting for attention. The null hypothesis usually claims that nothing is happening, while the alternative suggests that something significant is at play.

In engineering, we often formulate these hypotheses to test assumptions. For example, an engineer might hypothesize that a new manufacturing process reduces defect rates. The null hypothesis would be that there is no difference in defect rates between the old and new processes.

Various tests exist for hypothesis testing, including t-tests and chi-square tests. T-tests help compare means between two groups, making them handy for experiments. For instance, if an engineer wants to compare the tensile strength of two different materials, a t-test can help determine if the difference is statistically significant.

On the other hand, chi-square tests deal with categorical data. Engineers might use this test to determine whether a particular manufacturing process affects the quality of products. It’s like checking if a specific method leads to more defects—essential for quality control in production.

If you’re looking to deepen your understanding of hypothesis testing, The Signal and the Noise by Nate Silver provides insightful perspectives on prediction and uncertainty.

Nonparametric Tests

Nonparametric tests are the unsung heroes of statistics. They come into play when data doesn’t fit the assumptions of traditional tests. For instance, if the data is not normally distributed or if you’re dealing with ordinal data, nonparametric tests save the day.

These tests are especially useful in engineering when you can’t assume the underlying data follows a specific distribution. Imagine you’re assessing customer satisfaction across different product versions. The data might be ranks rather than exact scores, making nonparametric methods ideal.

Some common nonparametric tests include the Wilcoxon signed-rank test and the Mann-Whitney U test. The Wilcoxon test is great for comparing two related samples, while the Mann-Whitney U test compares two independent samples. These methods provide engineers with flexibility in analysis, ensuring they can obtain meaningful insights even with less-than-ideal data.

Regression and Correlation

Simple Linear Regression

Simple linear regression is like having a trusty sidekick in the world of data analysis. It helps engineers model the relationship between two variables—one independent and one dependent. Think of it as drawing a line through a scatter plot of data points, indicating how changes in one variable affect another.

This technique is particularly relevant in engineering when making predictions. For example, an engineer might want to predict the lifespan of a bridge based on the materials used. By applying simple linear regression, they can analyze historical data to establish a relationship between materials and longevity.

The beauty of regression lies in its simplicity and clarity. Engineers can use the resulting equation to forecast outcomes. If, based on past data, a specific material typically lasts 20 years, that’s a powerful insight for future projects. Simple linear regression thus serves as a foundational tool for predictive modeling, enabling engineers to make data-driven decisions.

Multiple Linear Regression

Multiple linear regression is a statistical technique that helps us understand the relationship between several independent variables and a dependent variable. Picture it like hosting a dinner party where you want to find out how different dishes affect your guests’ satisfaction. You might consider factors like the main course, dessert, and even the ambiance. Similarly, engineers use multiple linear regression to analyze how various factors influence outcomes in projects.

In engineering, this method is crucial. For example, when designing a new product, engineers can assess how materials, manufacturing processes, and design elements impact performance. By incorporating multiple variables, they can build a more accurate model that reflects real-world complexity. This approach not only enhances predictions but also helps identify which factors have the most significant impact.

Design of Experiments

Fundamentals of Experimental Design

Designing experiments is vital in engineering. It ensures that experiments yield reliable and valid results. Think of it as setting the stage for a theatrical performance; if the stage is poorly designed, the show suffers. Similarly, a well-thought-out experimental design can illuminate the truth behind engineering phenomena.

Key principles guide effective experimental design, with randomization and replication leading the charge. Randomization helps eliminate bias by ensuring that every participant or trial has an equal chance of being selected. This is like mixing a bag of candy; each piece has an equal shot at being picked. Replication, on the other hand, involves repeating experiments to confirm results. It’s akin to double-checking your homework to ensure accuracy. Together, these principles create a robust framework that enhances the reliability of engineering experiments.

For those looking for a deeper understanding of experimental design, consider reading Statistics for Research: With a Guide to SPSS by George Argyrous. It’s a great resource for understanding how to apply statistics in research settings!

Analysis of Variance (ANOVA)

ANOVA, or Analysis of Variance, is a statistical method used to compare means across multiple groups. In engineering, it’s particularly useful when assessing the effects of different factors on a dependent variable. Imagine an engineer testing three types of concrete to see which performs best under stress. ANOVA allows them to analyze variations between the groups to determine if the differences are statistically significant.

Case studies abound that showcase the effectiveness of ANOVA in engineering. For instance, a study might compare the tensile strength of steel beams subjected to different treatments. By using ANOVA, engineers can identify whether one treatment significantly outperforms the others. This kind of analysis not only streamlines decision-making but also enhances the quality of engineering designs.

Statistical Quality Control

Introduction to Quality Control

Quality control is a cornerstone of engineering practices. It involves ensuring that products meet specified standards and function reliably. Think of it as a safety net that catches defects before they reach consumers. Statistical methods play a pivotal role in this process, allowing engineers to monitor production and identify potential issues.

Engineers employ various statistical tools for quality assurance. Control charts, for instance, help track process variations over time. By analyzing data from production lines, engineers can detect trends that signal potential problems. This proactive approach minimizes defects, ensuring that products not only meet but exceed expectations.

For a comprehensive guide on statistical quality control, consider reading Control Charts: Practical Guide to Using Statistical Quality Control by Dale H. Besterfield. This book is a great resource for learning how to implement quality control in engineering!

Control Charts

Control charts are essential tools in statistical quality control. They provide a visual representation of process stability over time. Picture a roller coaster; if the ride goes off the rails, it’s crucial to know when and why. Control charts help engineers identify patterns that may indicate a problem, allowing them to intervene before issues escalate.

In manufacturing, control charts are widely used to monitor production processes. For example, if a factory produces light bulbs, control charts can track the number of defects over time. If defects rise above a predetermined threshold, engineers can investigate and make necessary adjustments. This method not only enhances product quality but also fosters a culture of continuous improvement within organizations.

Control charts are not just for manufacturing. They’re used in service industries too. For instance, hospitals monitor patient wait times using control charts. By analyzing data over time, they can identify trends and improve service efficiency. This proactive approach enhances patient care, showcasing the versatility of control charts.

Conclusion

Applied statistics and probability are indispensable in engineering. These concepts empower engineers to make informed decisions, optimize processes, and tackle complex challenges. By leveraging statistical tools, engineers can quantify uncertainty and enhance reliability in their projects.

The importance of these tools cannot be overstated. In fields ranging from civil to mechanical engineering, statistics provides a framework for problem-solving. It helps in analyzing data, predicting outcomes, and ensuring quality control. The insights gained from applied statistics can lead to safer, more effective designs and processes.

Moreover, understanding probability allows engineers to assess risks. It helps them make decisions based on data rather than intuition alone. For example, when designing a bridge, engineers can use statistical methods to determine load capacities and material strengths. This leads to safer structures and ultimately saves lives.

Engineers are encouraged to embrace statistical tools. These methods can streamline workflows, reduce errors, and enhance overall productivity. By incorporating applied statistics and probability into their practices, engineers can improve decision-making and problem-solving abilities.

To further your knowledge, consider diving into textbooks, online courses, or workshops focused on these topics. Resources like “statistics hypothesis testing cheat sheet” by Douglas C. Montgomery and George Runger offer practical insights and real-world applications.

In conclusion, applied statistics and probability are not just academic concepts. They are powerful tools that can significantly impact engineering practices. By mastering these skills, engineers can enhance their careers, contribute to safer designs, and drive innovation within their fields.

Frequently Asked Questions (FAQs)

What is the difference between descriptive and inferential statistics?

Descriptive statistics summarize data from a sample. They provide simple summaries about the sample and the measures. Inferential statistics, on the other hand, make predictions or inferences about a population based on a sample. Think of it as gathering a small slice of cake to guess the whole flavor!

How can statistics improve engineering processes?

Statistics improve engineering processes by providing tools to analyze data effectively. They help identify trends, optimize designs, and ensure quality control. For example, engineers can use statistical methods to analyze material performance, leading to better, safer products.

What resources are recommended for further learning?

Several resources can enhance your understanding of applied statistics and probability. Books like ‘Applied Statistics and Probability for Engineers’ by Montgomery and Runger are excellent starting points. Online platforms like Coursera and edX also offer courses on these topics.

Please let us know what you think about our content by leaving a comment down below!

Thank you for reading till here 🙂

All images from Pexels