Introduction

Industrial analytical services involve testing and evaluating materials. They play a vital role in quality control and regulatory compliance. These services are essential across various sectors, ensuring products meet safety and performance standards. From pharmaceuticals to manufacturing, analytical solutions help organizations maintain their reputation and efficiency.

To enhance your laboratory’s capabilities, consider investing in a Spectrophotometer. This essential tool can provide precise measurements for various applications, ensuring your analyses are as accurate as possible. Imagine the peace of mind knowing you have reliable data to back your findings!

Summary and Overview

Industrial analytical services encompass various techniques aimed at ensuring product quality and compliance. Methods include chemical analysis, physical testing, and microbiological assessments. Each technique is crucial for meeting stringent regulatory requirements. These services support industries such as pharmaceuticals, food and beverage, and environmental sectors.

In fact, the market for industrial analytical services is growing rapidly, with an expected 7.5% CAGR from 2023 to 2030. Regulatory compliance is not just a necessity; it can also enhance operational efficiency. By optimizing processes, businesses can lower costs while improving product quality. Companies must prioritize these services to remain competitive in today’s market.

For companies looking to streamline their operations, investing in Quality Management System Software can be a game-changer. This software helps businesses maintain compliance and improve quality while saving time and resources.

Types of Industrial Analytical Services

Chemical Analysis

Chemical analysis involves various testing methods to assess material composition. Common techniques include spectroscopy and chromatography. These methods are crucial in industries like pharmaceuticals and petrochemicals. For instance, pharmaceutical companies rely on chemical analysis to ensure drug safety. In petrochemicals, it helps determine the quality of fuels and lubricants.

For those diving deeper into chemical analysis, consider the Chromatography Equipment. This essential equipment can help you separate mixtures and analyze substances effectively, making it a must-have for any serious lab.

Physical Testing

Physical testing evaluates the mechanical properties of materials. Methods like tensile strength and hardness testing are widely used. These tests play a vital role in manufacturing and materials science. They help ensure that products meet safety and performance standards. For example, car manufacturers test materials to guarantee vehicle safety under stress.

If you’re serious about testing materials, investing in a Tensile Testing Machine can provide you with the accuracy needed for critical assessments. Whether you’re testing metals, plastics, or textiles, this machine will help ensure your materials meet industry standards.

Environmental Testing

Environmental compliance is critical for industries today. Testing services assess air, water, and soil quality. These tests help organizations meet regulatory requirements. For instance, companies must ensure that wastewater meets legal standards to protect ecosystems. Environmental testing is essential for sustainable business practices.

To ensure you’re meeting those environmental standards, invest in Environmental Testing Equipment. This equipment will help you monitor and analyze environmental factors, ensuring compliance with regulations while protecting our planet.

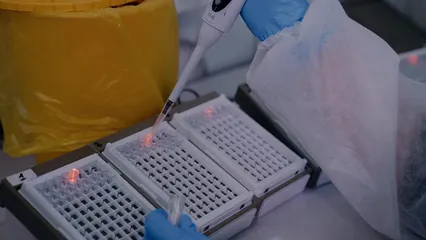

Microbiological Testing

Microbiological testing is key in food safety and pharmaceuticals. It helps detect harmful bacteria and pathogens. Methods like culture testing and polymerase chain reaction (PCR) are standard. Adhering to standards such as ISO ensures accurate results. This testing safeguards public health by ensuring products are free from contaminants.

For effective microbiological testing, consider using PCR Testing Kits. These kits are essential for detecting pathogens quickly and accurately, ensuring the safety of your products and the health of your customers.

Quality Control and Assurance

Quality management systems (QMS) are vital for maintaining high standards. Certifications like ISO 9001 and ISO 17025 demonstrate a commitment to quality. These certifications assure customers that products meet global standards. Implementing a QMS not only improves efficiency but also boosts consumer trust in products.

For a comprehensive understanding of quality management, check out the ISO 9001 Certification Guide. This guide will equip you with the knowledge to implement a robust quality management system, enhancing your operational efficiency and customer satisfaction.

Innovations in Industrial Analytical Techniques

Emerging Technologies

New technologies are transforming analytical testing. Artificial intelligence (AI) and machine learning are at the forefront. These advancements significantly enhance efficiency and accuracy in data analysis. AI algorithms can quickly process large datasets, identifying trends and anomalies faster than traditional methods. As a result, companies can make informed decisions quickly, reducing the time from analysis to action. This shift not only optimizes workflows but also boosts overall productivity in various industries.

For those interested in the intersection of AI and analytical chemistry, the book AI for Analytical Chemistry is a must-read. This book explores how AI is revolutionizing the field and offers insights into its applications in data analysis and decision-making.

Automation in Analytical Processes

Automation is revolutionizing analytical processes across sectors. Automated testing solutions streamline operations, minimize human error, and increase throughput. For example, in the pharmaceutical industry, automated systems can perform high-throughput screening of drug compounds, yielding results in a fraction of the time. Case studies show that manufacturers adopting automation have seen substantial cost savings and improved consistency in their results. This trend indicates a bright future for industries willing to embrace technology in their analytical practices.

For those looking to automate their laboratory processes, consider investing in Automated Laboratory Equipment. This equipment can significantly reduce manual intervention, ensuring quicker results and freeing up your staff for more critical tasks.

Challenges in Industrial Analytical Services

Regulatory Compliance

Regulatory compliance is a major concern for analytical services. Various regulations impact testing standards, from environmental controls to product safety. Companies must stay updated on these regulations to avoid penalties. Strategies for maintaining compliance include regular training for staff and investing in updated technology. Developing a robust quality management system can help organizations navigate these complexities effectively.

Data Management

Data integrity and security are paramount in analytical services. Handling large datasets presents unique challenges, including data storage and accessibility. Companies often struggle with ensuring the accuracy and reliability of their data. Implementing strong data management practices is essential. This includes regular audits and using secure cloud-based storage solutions. By prioritizing data management, organizations can protect sensitive information and enhance their analytical capabilities.

For effective data management, consider investing in Data Management Software. This software will help you organize, store, and analyze your data securely, making it easier to maintain compliance and access critical information when needed.

Skill Shortages

The demand for skilled analysts in industrial analytical services is increasing. Many industries struggle to find qualified professionals. This skill gap can lead to delays in compliance and quality assurance.

To address this issue, companies must invest in training and development programs. Implementing mentorship programs can pair experienced analysts with newcomers. Additionally, partnerships with educational institutions can cultivate a talent pipeline. Offering continuous education ensures analysts stay updated with industry advancements.

By focusing on skill development, businesses can enhance their analytical capabilities and maintain high standards.

Case Studies

Successful Implementation of Analytical Services

Consider a pharmaceutical company that adopted advanced analytical services. This integration enabled them to streamline quality control processes. As a result, they reduced product defects by 30%. Another case involved a food manufacturer that implemented rigorous microbiological testing. This step not only ensured compliance but also boosted consumer trust, leading to a 25% increase in sales.

These examples highlight how effective analytical services can drive significant improvements in quality and efficiency across industries.

Conclusion

In summary, industrial analytical services play a critical role in maintaining quality, compliance, and efficiency. As industries face increasing regulations, the need for skilled analysts becomes paramount. Businesses should evaluate their analytical needs and invest in appropriate services to thrive in a competitive landscape. Take action now to secure the future of your organization through robust analytical solutions.

FAQs

What are industrial analytical services?

Industrial analytical services provide testing and evaluation for materials. They encompass various techniques, including chemical analysis and microbiological testing. These services help businesses ensure product quality, safety, and compliance with regulations.

How do industrial analytical services ensure compliance?

These services adhere to regulatory frameworks like ISO, ASTM, and EPA standards. They help businesses meet legal requirements for product safety and environmental protection. Regular audits and testing ensure ongoing compliance with industry regulations.

What industries benefit from industrial analytical services?

Several key industries rely on these services, including: Pharmaceuticals: Ensuring drug safety and efficacy. Food and Beverage: Testing for contaminants and quality assurance. Environmental: Monitoring air, water, and soil quality. Manufacturing: Quality control of raw materials and finished products.

How can businesses choose the right analytical service provider?

When evaluating potential providers, consider these tips: Check Qualifications: Ensure they have relevant certifications and accreditations. Review Expertise: Look for experience in your specific industry. Assess Capabilities: Verify the range of analytical techniques offered. Read Reviews: Seek testimonials and case studies from previous clients.

What are the latest trends in industrial analytical services?

Emerging technologies are shaping the future of analytical services. Key trends include: AI and Machine Learning: Enhancing data analysis and predictive capabilities. Automation: Streamlining testing processes for efficiency and accuracy. Sustainability: Increasing focus on eco-friendly practices and materials. These innovations are driving improvements in efficiency and reliability across various industries.

Please let us know what you think about our content by leaving a comment down below!

Thank you for reading till here 🙂

All images from Pexels